Laser Distance Measurer: Difference between revisions

No edit summary |

|||

| Line 65: | Line 65: | ||

== Results == | == Results == | ||

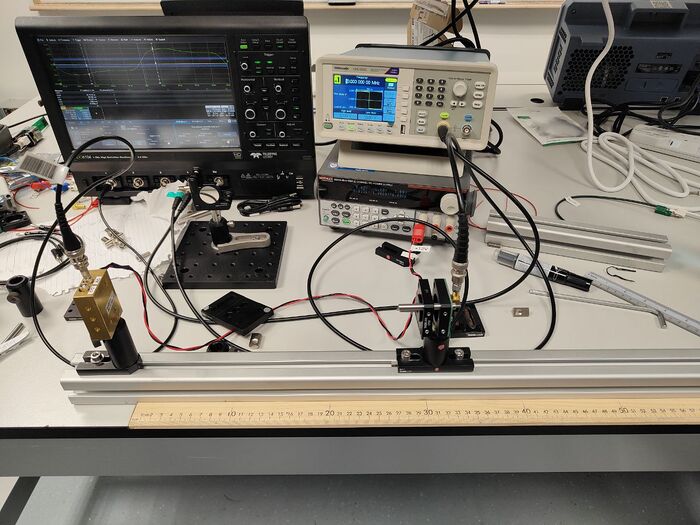

[[File:Distance_of_LED_to_Detector_vs_Measured_Delay_TIme_on_Oscilloscope_WITHOUT_Mirror.jpeg|500px|thumb|center]] | [[File:Distance_of_LED_to_Detector_vs_Measured_Delay_TIme_on_Oscilloscope_WITHOUT_Mirror.jpeg|500px|thumb|center|Distance of LED to detector vs. Measured delay time on oscillascope (path of light is a straight line)]] | ||

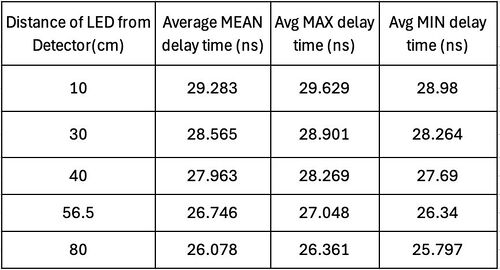

[[File:delaytimewithmirror.jpeg|500px|thumb|center]] | [[File:delaytimewithmirror.jpeg|500px|thumb|center|Distance of LED to detector vs. Measured delay time on oscillascope (path of light is reflected by a mirror)]] | ||

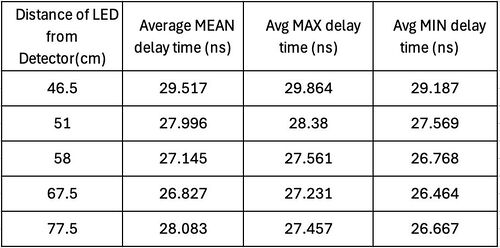

[[File:calculatedwithoutmirror.jpeg|600px|thumb|center]] | [[File:calculatedwithoutmirror.jpeg|600px|thumb|center]] | ||

Revision as of 13:59, 28 April 2025

Group Members

Arya Chowdhury, Liu Sijin, Jonathan Wong

Background and Theory

Equipment List

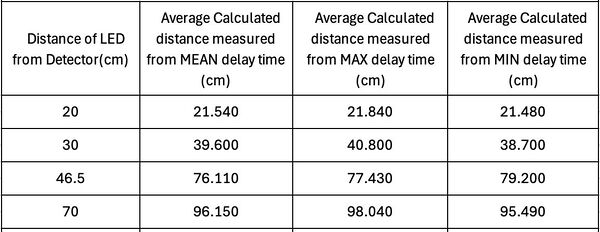

Experimental Work

2.1 Procedure

2.1.1 Laser Modulation and System Initialisation

Configure the function generator (Tektronix AFG1022) to output a 10 MHz square wave with an amplitude of 0–3.1 V (High level: 3.1 V, Low level: 1.0 V, output impedance: 50 Ω) to modulate the laser diode. Use the Keithley 2231A-30-3 DC power supply to provide 5.0 V to the laser driver circuit, with a current limit of 30 mA. Verify the laser beam stability to avoid multimode noise or thermal drift that could distort the modulation waveform.

2.1.2 Optical Alignment

Mount the 650 nm laser diode and use an aspheric lens to collimate and focus the beam onto the reflective target surface.

|

|

| Figure 1. Front view of collimating lens for laser diode | Figure 2. Side view of collimating lens for laser diode |

2.1.3 Detection and Amplification Circuit Configuration

For the photodetector, a Hamamatsu S5971 silicon photodiode was used to detect the reflected light signal. To amplify the signal linearly without saturation, connect the detector output to a matched high-speed preamplifier (bandwidth >100 MHz, gain ~10³–10⁵). Connected the amplifier output to Channel 2 of a digital oscilloscope; connect the reference signal from the function generator to Channel 1 as the modulation phase reference.

|

| Figure 3. Hamamatsu S5971 silicon photodiode with amplifier |

2.1.4 Time Delay vs. Distance Mapping

Fix the LED source and the photodetector on a linear translation stage, ensuring proper alignment for the beam return to the detector at all positions along the translation stage. The detector and the laser diode were mounted on a postholder so that the height of the detectors was adjustable. Turn on the LED and ensure that the beam is collimated by adjusting the distance of the lens to the LED. Incident the LED onto the photodetector and observe the function generated on the oscilloscope. Use the oscilloscope’s cursor measurement function to determine the relative time delay Δt between the modulation reference signal (Channel 1) and the return signal (Channel 2). Correlate the measured delay values with corresponding distances to establish the system’s delay–distance response curve. The following are the steps carried out to measure the time delay and the corresponding distance.

- Fix the LED source and the photodetector on a linear translation stage, ensuring proper alignment for the beam return to the detector at all positions along the translation stage; the detector and the laser diode were mounted on a postholder so that the height of the detectors was adjustable.

- Use a meter ruler to mark the distance along the translation stage.

- Move the LED source to the marked positions (e.g. 30 cm from detector) and adjust the beam until it is centralised on the photodetector.

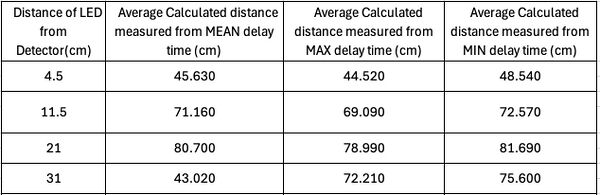

- Measure the time delay on the oscilloscope. Record the minimum, maximum and mean time delay—take three readings per distance and average them.

- Repeat steps 1–4 for different distances on the translation stage.

- Insert a mirror in the setup to act as the “object we are trying to measure the distance of”, so that the beam path is reflected off the mirror to the photodetector.

- Measure the total path length manually and repeat steps 1–4 for each mirror position.

2.2 Measurement techniques

Results

Challenges and Conclusion

1. One of the challenges we faced was centring the beam onto the photodetector. Due to the lack of a focusing beam on the photodetector, the laser beam spot size was much larger than the surface area of the photodetector. What this led to was a constant fluctuation of the delay time on the oscilloscope as the brightest part of the beam was not always centred on the photodetector despite optimising stabilisation of the beam path.

2. To have accurate distance measurements in the centimetre regime, the delay time we required was ~0.3ns for every 10cm. However, the fluctuation of the delay time on the oscilloscope was causing the 1st decimal place to fluctuate constantly.

Improvements and Future Work

1. Install a focusing lens for the photodetector

2. Use a bandpass filter at 650nm laser to filter out other frequencies to get less fluctuations in the delay time reading on the oscilloscope.