Humidity Sensor of Graphite: Difference between revisions

| Line 25: | Line 25: | ||

The DHT11 is a temperature and humidity composite sensor with calibrated digital signal output, suitable for measuring ambient temperature and humidity. It adopts special digital module acquisition technology, providing high reliability and long-term stability. It is widely used in environmental monitoring, industrial control, home automation, and other fields. | The DHT11 is a temperature and humidity composite sensor with calibrated digital signal output, suitable for measuring ambient temperature and humidity. It adopts special digital module acquisition technology, providing high reliability and long-term stability. It is widely used in environmental monitoring, industrial control, home automation, and other fields. | ||

==== Basic | ==== Basic Specifications ==== | ||

{| class="wikitable" style="text-align:center; width:60%" | {| class="wikitable" style="text-align:center; width:60%" | ||

Revision as of 01:30, 29 April 2025

Team Member

Xu Ruizhe, Ma Shunyu, Li Zerui, Wei Heyi

Introduction

Humidity sensors play an essential role in fields such as environmental monitoring, industrial process control, agriculture, and healthcare, where accurate humidity measurements are critical. High-quality sensors are necessary to precisely track humidity levels and variations. Traditionally, materials like metal oxides and polymers have been used, but they often suffer from limitations including slow response times, low sensitivity, and limited accuracy.

In recent years, carbon-based materials have gained significant interest due to their unique physical and chemical properties. They offer remarkable features such as high surface area, excellent electrical conductivity, and strong chemical stability across various environments. These advantages make carbon materials highly promising for developing sensitive and reliable humidity sensors. For instance, carbon nanotubes (CNTs) enhance sensor response speed thanks to their large surface area and porosity, while graphene provides ultra-fast signal transduction owing to its thin structure and superior conductivity. Other forms like carbon black and carbon fiber show strong resistance to humidity-induced degradation, ensuring long-term operational stability.

The humidity sensing capability of carbon-based materials largely stems from their interaction with water molecules. Changes in humidity cause adsorption or desorption of water on the material surface, altering properties such as resistance or capacitance. Sensor performance can further be tailored by adjusting material morphology or engineering defects.

In conclusion, carbon-based materials offer exciting prospects for future humidity sensing technologies. By continuously improving their physicochemical properties through nanotechnology and materials engineering, it is possible to develop sensors with greater sensitivity, faster response, and broader adaptability to complex humidity environments.

Objective

(1) Build a a sealed drying chamber: use a dry box; control the humidity by desiccants and hot water.

(2) Monitor the humidity with sensor: use DHT11 sensor to monitor the humidity and temperature inside the chamber; verify the range of humidity.

(3) Measure the resistance of Graphite sensor: use Arduino to measure the resistance; record the data with Python code.

(4) Data analysis: use Python code to do fitting; get the experimental relationship between Graphite's resistance and humidity; analyze the error.

Experimental Principle

DHT11

The DHT11 is a temperature and humidity composite sensor with calibrated digital signal output, suitable for measuring ambient temperature and humidity. It adopts special digital module acquisition technology, providing high reliability and long-term stability. It is widely used in environmental monitoring, industrial control, home automation, and other fields.

Basic Specifications

| Parameter | Value |

|---|---|

| Temperature Range | 0 – 50°C |

| Temperature Accuracy | ±2°C |

| Humidity Range | 20 – 90% RH |

| Humidity Accuracy | ±5% RH |

| Operating Voltage | 3.3 – 5.5 V |

| Max Current during Measurement | 2.5 mA |

| Sampling Period | ≥ 1 second |

| Signal Output | Digital (single-wire) |

| Size | Approx. 15.5mm × 12mm × 5.5mm |

Equipment Required

Alcohol molecules exhibit distinct absorption characteristics in the infrared spectrum due to the vibrational modes of specific functional groups, particularly the hydroxyl (-OH) and methyl (-CH₃) groups. These groups interact with infrared light at specific wavelengths, leading to unique absorption peaks that can be utilized for concentration measurement.

In the near-infrared (NIR) region, the wavelength range between 1250 nm and 1350 nm is particularly sensitive to ethanol concentration. Notably, around 1300 nm, ethanol demonstrates significant variations in absorption intensity that correlate directly with its concentration. This is primarily due to the overtone and combination vibrations of the C-H and O-H bonds, which result in measurable absorption differences as ethanol content changes.

By analyzing these absorption variations, it is possible to accurately determine alcohol concentration in a given sample. The wavelength of 1300 nm is chosen as the optimal measurement wavelength because it provides a clear and distinguishable response to ethanol concentration changes.

Objective

This experiment proposes a non-contact alcohol concentration measurement method by using infrared spectroscopy. This method measures changes in infrared light intensity transmitted through alcohol solutions, using a spectrometer and principal component analysis to achieve high precision measurements.

Advantages of Infrared-Based Alcohol Detection

- Non-contact measurement, reducing contamination.

- High accuracy, based on alcohol-specific infrared absorption characteristics.

- Low cost, with simple photodetection devices.

Equipment Required

- Different concentration of ethanol

- Cuvette

- LAMBDA 850 Spectrometer

Experiment Set Up

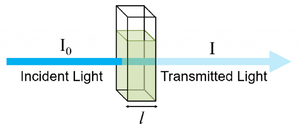

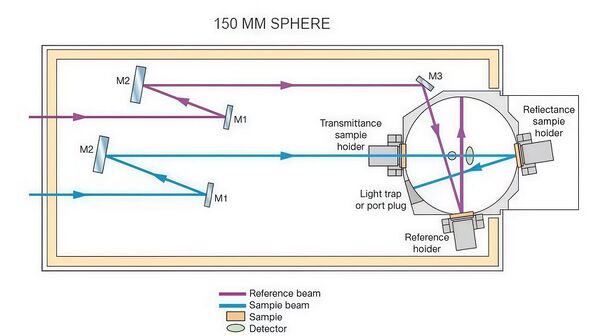

The LAMBDA 850+ UV-Visible-NIR spectrophotometer used for measurements is capable of precise spectral measurements within the wavelength range of 800 nm to 1400 nm, making it suitable for analyzing the absorption characteristics of substances such as alcohol molecules. The device is equipped with both a deuterium lamp and a tungsten-halogen lamp, providing UV and visible/near-infrared light sources, respectively. The high-quality master-engraved holographic grating monochromator ensures precise wavelength control, guaranteeing high-resolution spectral measurements.

The core of the device includes a high-sensitivity R6872 photomultiplier tube (PMT) detector, ensuring accurate signal collection across a broad wavelength range from UV to near-infrared. In the analysis of the effect of alcohol concentration changes on absorption intensity, the LAMBDA 850+ provides high sensitivity and precise measurements.

With this high sensitivity and precision configuration, it provides strong support for the optical property analysis of solutions such as alcohol, especially excelling in peak absorption location and concentration variation analysis.

Experiment Procedures

- Preparation of alcohol solutions at concentrations of 25%, 50% and 75%.

- Measurement of absorption using spectrometer.

- Use Origin software for spectral normalization and baseline correction, and process the alcohol spectra at three different concentrations.(Due to the subtle differences in the spectral data, it is difficult for non-experts to visually distinguish between the spectra of the three alcohol concentrations. Therefore, machine learning-based Principal Component Analysis (PCA) is applied for spectral classification, enabling accurate measurement of alcohol concentration.)